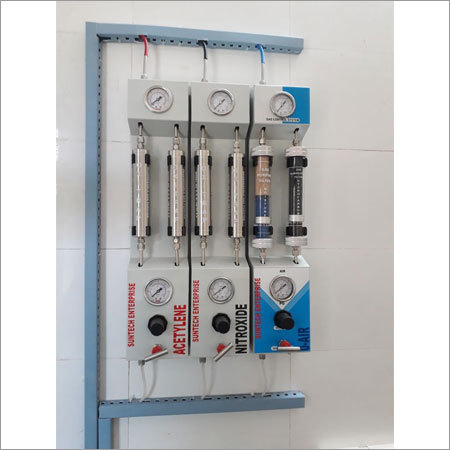

Gas Purification Panel

Price 1000.00-10000000.00 INR/ Unit

MOQ : 1 Unit

Gas Purification Panel Specification

- Product Type

- Gas Purification Panel

- Flow Rate

- 2-50 Nm3/hr (depending on model)

- Pressure Range

- 0-300 bar

- Technics

- Welded and Modular Construction

- Outlet Size

- 1/4 to 1/2 NPT/BSP

- Material

- Stainless Steel

- Features

- Multi-stage Filtration, Wall Mounting, Inlet/Outlet Isolation Valves, High Purity Components, Pressure Gauge

- Usage & Applications

- Laboratories, Industrial Gas Supply, Analytical Instruments, Research Facilities

- Gas Type

- Nitrogen, Hydrogen, Helium, Argon, CO2, Specialty Gases

- Metal Type

- SS 304/316

- Application

- Gas Distribution and Purification

- Size

- Standard/Custom as per requirement

- Weight

- 18-35 kg (varies with configuration)

Gas Purification Panel Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cheque, Cash Advance (CA)

- Supply Ability

- 30 Units, , Per Month

- Delivery Time

- 3-4 Week

- Main Domestic Market

- Gujarat, All India

About Gas Purification Panel

Approx Price: Rs 7,000 /Piece

Minimum Order Quantity : 1 Piece

Product Details :

| Finish | Epoxy Polyester Powder Coated |

| Brand | Suntech |

| Body Material | Mild Steel |

| Port Size | 1/4 Inch or 1/8 Inch |

| Inlet Pressures | 16 bar |

| Hydrocarbon Trap | Yes |

| Gas Requirements | N2,Air,He,H2 |

| Flow rate | 250 LPM |

| Condition | New |

Features :This Gas Purification Panel is used in the domain of Gas Chromatography for the column & the detector. Different problems are caused in Gas Chromatography analysis by impure gases, hence they have to be purified and freed from moisture, Oxygen, Hydrocarbons, etc. Moisture and oxygen damage the GC column and hydrocarbons cause baseline noise.

- Gas Purification Panel effectively removes hydrocarbons, oxygen, moisture, oil and other materials from gas streams. It also eliminates noise and signals of gases to get peak resolution and tailing in the analysis. The carrier gas is passed through oxygen, moisture and hydrocarbons removal filters and hydrogen is passed through moisture removal filler. The streams of gas are controlled by a steady pressure regulator. The inlet and outlet pressure is displayed on gauge. It can be easily wall mounted. In addition to this, it also reduces baseline noise and drift issues.

Multi-Stage Purity Assurance

Equipped with a 3-stage purification systemPre Filter, Main Filter, and Final Filterthis panel effectively removes particulate, moisture, and chemical impurities to deliver ultra-high purity gases. The integrated moisture trap and precision leak testing at 1.5x operating pressure further assure reliability for critical applications.

Flexible Installation & Customization

Choose from wall-mounted or skid-mounted panels, with customizable sizing and color options to match any application or interior. The unit supports both SS tube and compression fittings, while manifold configurations allow for single, double, or multi-line operation, accommodating a wide range of system requirements.

Comprehensive Accessories & Safety Features

Supplied with essential accessories like pressure regulators, non-return and pressure relief valves, mounting clamps, and optional features such as digital pressure indicators, flow meters, and remote alarm systems. These inclusions streamline installation, operation, and ongoing monitoring for user safety and convenience.

FAQs of Gas Purification Panel:

Q: How does the 3-stage filtration system in the gas purification panel work?

A: The panel utilizes a sequential 3-stage filtration process: a pre-filter removes coarse particulates, the main filter targets smaller particulates and moisture, and the final filter eliminates minute impurities, achieving gas purity levels up to 99.9999%. This ensures consistently pure gas output for sensitive applications.Q: What is the installation process for wall-mounted or skid-mounted purification panels?

A: Installation involves securing the panel on a wall or skid using mounting clamps, connecting compatible SS tube or compression fittings, and integrating manifold options as needed. The panel is supplied with detailed instructions and is factory-tested to simplify commissioning.Q: When should the filters and accessories in the gas purification panel be maintained or replaced?

A: Maintenance schedules depend on gas type, flow rates, and operational conditions. Generally, filters should be inspected and replaced periodically, as recommended in the user manual, to maintain purity and performance. Accessories like pressure regulators and gauges should also be checked routinely.Q: Where is the gas purification panel suitable for use?

A: This panel is designed for use in laboratories, analytical instrument setups, industrial gas distribution systems, and research facilitiesanywhere ultra-high purity gases are critical. Its robust construction and configurable design make it adaptable for various environments.Q: What are the benefits of having an integrated moisture trap and factory-performed leak testing?

A: The integrated moisture trap protects the filtration system from water contamination, ensuring longer filter life and consistent gas quality. Factory leak testing at 1.5x operating pressure guarantees safety, operational reliability, and compliance with stringent industry standards.Q: How does the gas purification panel support customized applications and gases?

A: The panel can be customized for color, size, manifold count, and accepts a wide range of inlet and outlet fittings. It is compatible with multiple gasesincluding nitrogen, hydrogen, helium, argon, CO2, and specialty gasesserving diverse application needs efficiently.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS